ANCHOR RECEIVER

Wilks Fendering Selection Guide

We have an extensive range of Wilks fendering options, but choosing the perfect profile shouldn’t be complicated.

ANCHOR RECEIVER

This page outlines each fendering / rub rail category and how to find the right Wilks fendering. Download the PDF version here.

Find the Best Fit For You

MATCHING AN EXISTING FENDER?

For a seamless match to your current fendering profile, our Wilks fendering catalogue offers precise, life-size drawings enabling you to find the ideal profile. Once you have identified the correct profile, simply:

- Find it in the Wilks fendering web shop

- Choose the size, quantity, and colour

- Checkout

It is as simple as that!

If you are still unsure, continue reading the helpful selection guide below or contact our expert team directly.

ANCHOR RECEIVER

Types of Fendering

Wilks fendering products offer versatility and can be applied in various situations. The following guide will direct you to the perfect solution for your boat/application.

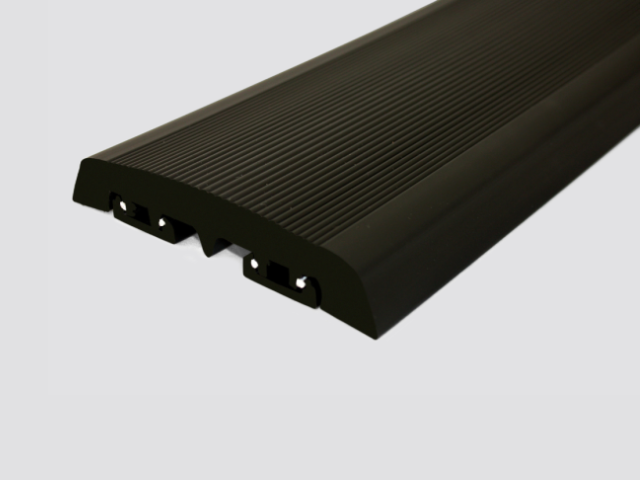

Click

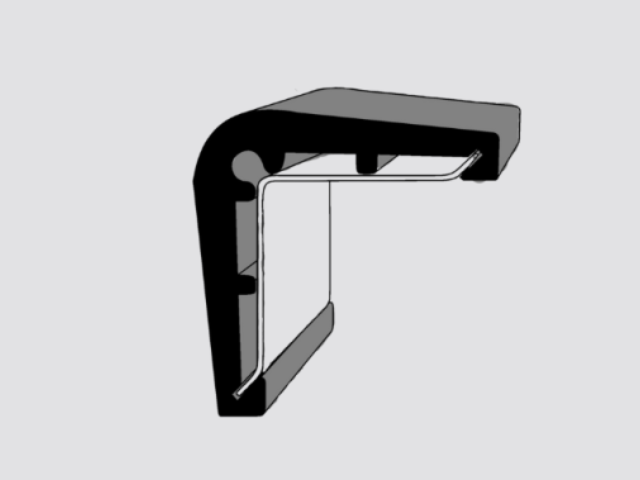

Click is the latest addition to the Wilks fendering range and is renowned for its clean, sleek look, simple installation without any unsightly fixings. The Click range is favoured for leisure boats and is available in 4 sizes, enabling you to find the perfect fit.

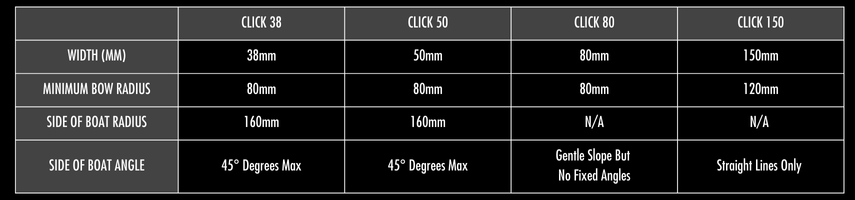

CLICK 38

Click 38 is the smallest of the Click range. A versatile profile, it can handle an 80mm bow radius and accommodate sloping the fendering down towards the transom. It can handle a 160mm radius with ease. Typically used higher on the hull / gunwale.

CLICK 50

Slightly larger than the Click 38 but just as versatile. It can also handle an 80mm bow radius and accommodate sloping down towards the transom. Typically used higher on the hull / gunwale.

CLICK 80

This adaptable profile can handle up to an 80mm bow radius. If you need to slope the fendering down towards the transom, this profile can cope with a gentle slope. Typically used higher on the hull / gunwale or lower near the swim deck / transom.

CLICK 150

The largest of our Click range. This profile has increased contact zones for greater security. Due to its profile size, Click 150 can only be installed along a level, horizontal line, with no vertical deviation, but it can navigate a minimum bow radius of 120mm. Typically used in lower areas near the swim deck/transom.

Check out the table below for more guidance for the best fit for your boat:

BUMP!

Bump! fendering seamlessly combines function and style whilst also providing easy installation for added convenience. Ideal for environments with higher contact, it adeptly handles curves of up to an 80mm radius, without the need to mitre any of the track or the body. There are no visible fixings once fitted. Available in 2 sizes, 53mm and 65mm and 3 colour choices, black, white, or traditional, so can match any style of boat, from classic to modern.

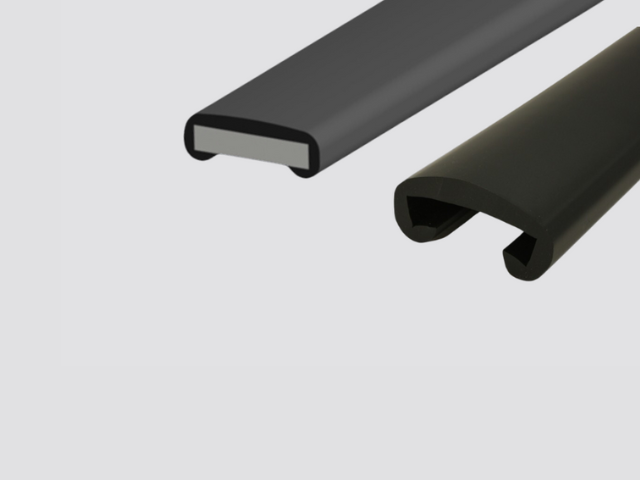

ALUMINIUM (ALI)

Our aluminium range of fendering offers a classic fendering solution whilst maintaining an elegant feel to the hull. With widths from 22mm to 83mm, there is sure to be one suitable for your boat. Our aluminium fendering is paired with a flexible PVC insert, offering resistance against bumps and scrapes. A key advantage lies in its visual appeal, as it creates a sleek and attractive line that complements the boats natural contours.

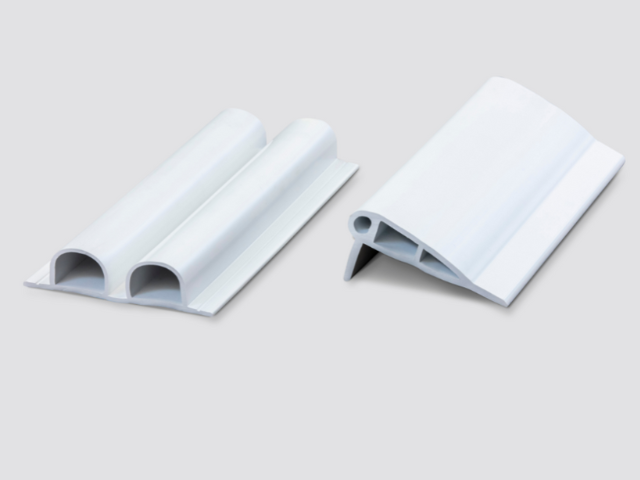

RIGID PVC FENDERING

Our range of Rigid PVC fendering offers a classic alternative to our aluminium fendering. It is ideal for casual or day cruisers. With a wide variety of stainless steel or PVC insert options depending on the body – we are sure to have the profile you are looking for.

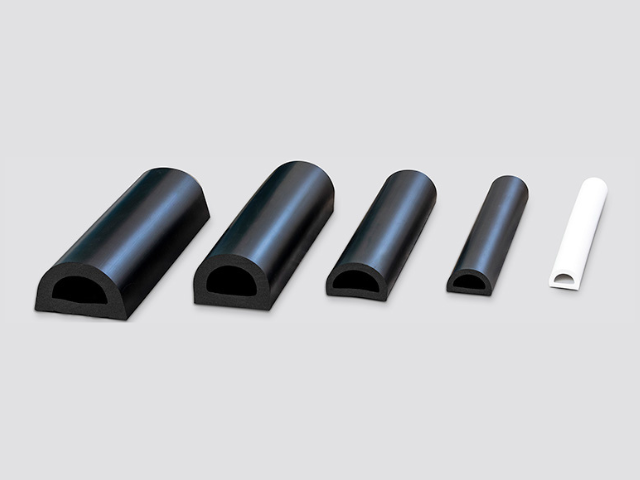

D FENDERING

D fendering offers excellent defence for boats, utilising their ‘D’ shape to provide ample surface area for any contact with docks or other vessels. Essentially absorbing some of the force and helping to avert damage. D fendering is one of the largest of Wilks ranges, so it’s never been easier to find D fendering for your boat. The classic ‘D’ profile excels in heavy-duty usage, particularly the larger sizes. Versatile and adaptable, D profiles are well suited for various industries and applications.

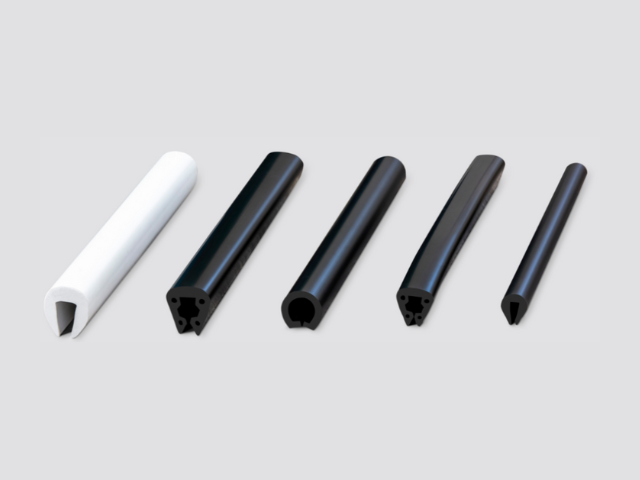

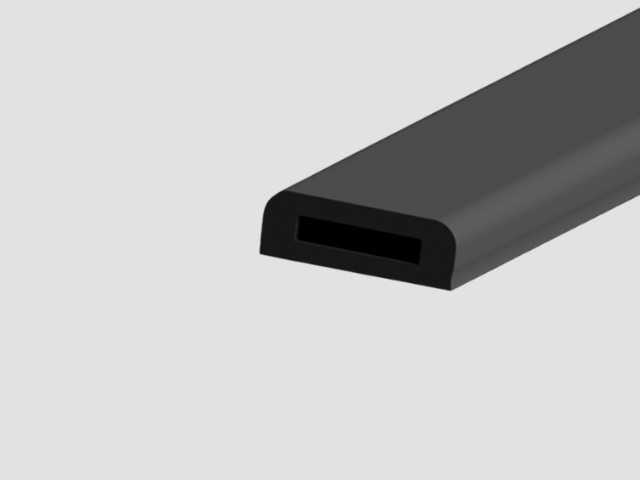

U FENDERING

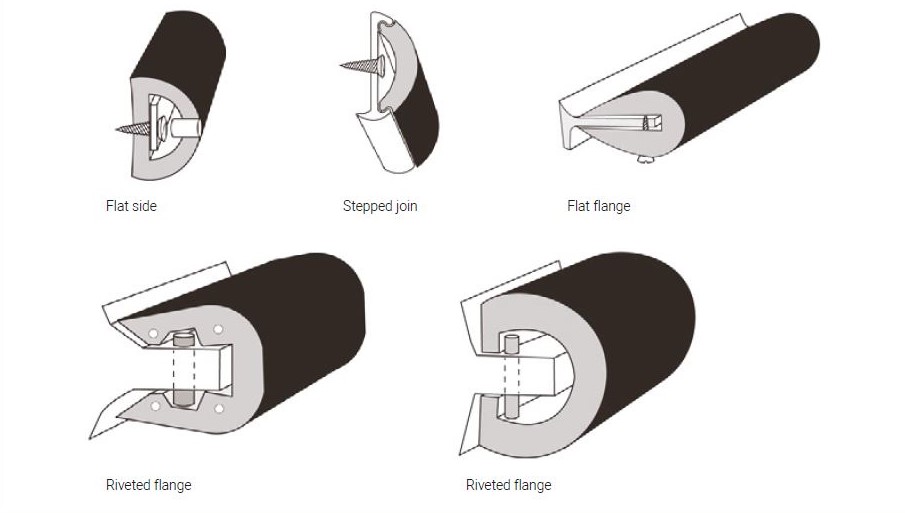

U profiles are designed to fit over a flange style join, to cover the vulnerable area. The wide array of U fendering comes in various shapes, allowing for seamless integration. Whether it is a flat or riveted flange, there is a U fender for you. U fendering is a quick and simple solution for smaller boats.

B FENDERING RANGE

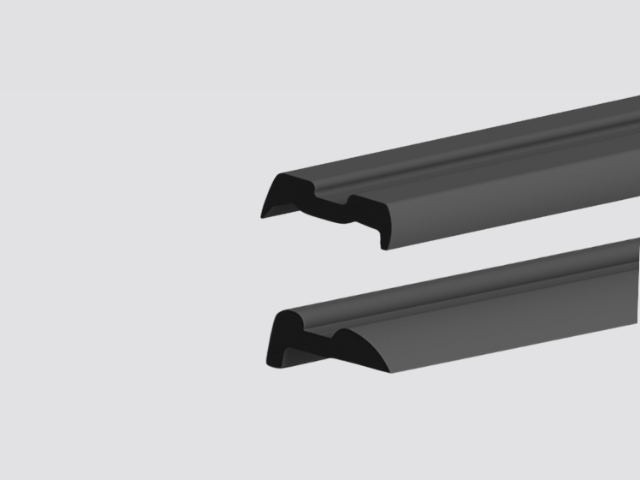

B profiles are both durable and reliable, making them well suited for busy environments. The B profiles allow for a high level of protection. As their B shape offers two points of contact, providing ample cushioning for your boat when needed.

PONTOON FENDERING

Our pontoon and dock fendering profiles have been designed with ease of installation in mind. The profiles provide lasting levels of protection over wood. Whilst sustaining a high-quality standard with minimal maintenance.

TRADITIONAL FENDERING RANGE

Our traditional range features woodgrain-finished fendering products, offering durability and timeless aesthetics. This range gives you the classic wood appearance, without the fuss. The traditional range is available in a selection of profiles including U’s, D’s, B’s, and Bump!

FLEXIBLE PVC PROFILES

Wilks flexible PVC profiles are a more malleable version of the popular rigid PVC range. Made with a slightly softer material, flexible PVC profiles are adept at handling curves and contours with precision and ease. This range is completed with a range of colourful PVC inserts for improved style and function.

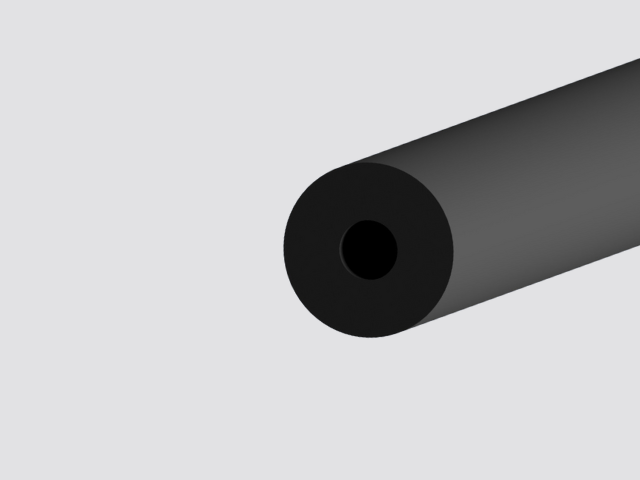

HOLLOW ROUND PROFILES

Hollow round profiles are known for their versatility, making them suitable for a variety of uses and environments. They offer durability and reliability for the marine sector and other industries alike. Additionally, these profiles are adaptable for different methods of installation, depending on use. For instance, one preferred method is using a strong metal wire through the centre to loop the profile around an object or boat.

EDGING TRIMS

When people say, “the devil is in the details”, they may be referring to edging trims and hatch seals. As a finishing product, they may be overlooked, but in actuality, the right one can provide a stylish and complete feel to the boat. As they can conceal the edges whilst adding an extra level of water protection. All profiles are suitable for fitting a 3mm thick panel. For hatches, the side seal edging trim (ET SS) is the most apt profile. For other applications, then ET 101 (White) or the ET 106 (Black) are more appropriate.

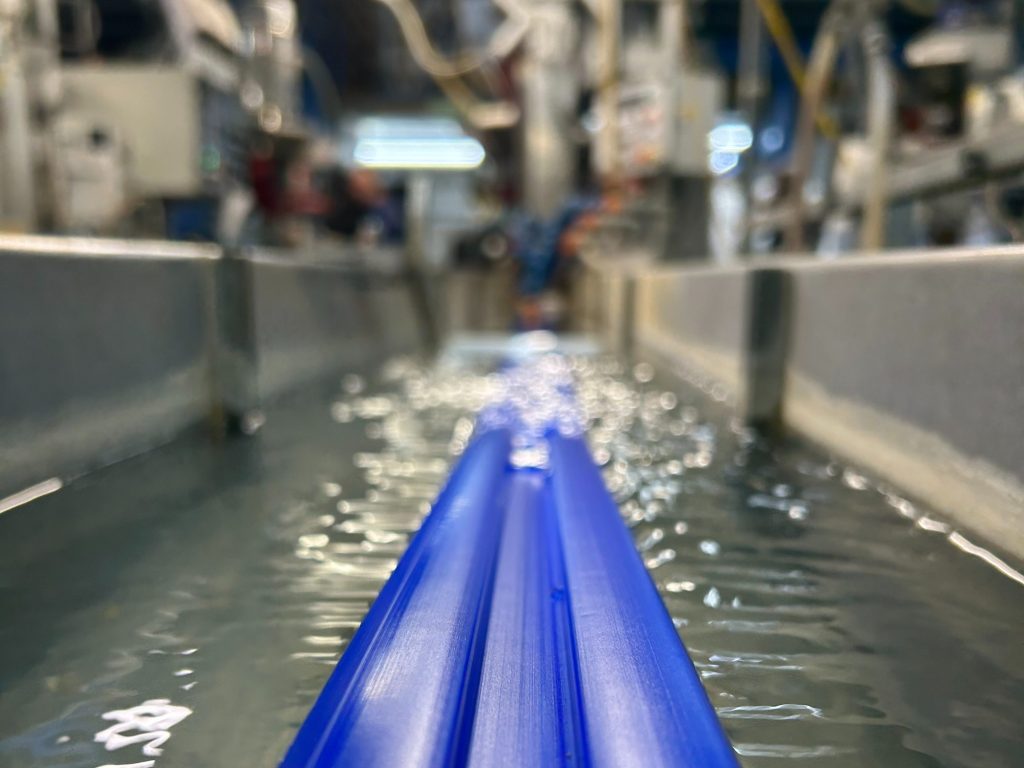

LOW FRICTION MDPE

Low friction profiles are made from MDPE (Medium Density Polyethylene) and offer a hard-wearing surface. Their MDPE material makes it ideal for enduring conditions in extreme climates – hot or cold. Whether for increased safety or style, Low Friction MDPE profiles are available in a bright blue. As well as a traditional Black.

BUFFERS

Wilks buffers provide a cushioned area for high contact zones in a multitude of environments, including marine and shop fitting. Paired with a rigid fixing strip for installation, the buffer will stay secure while offering high-quality protection.

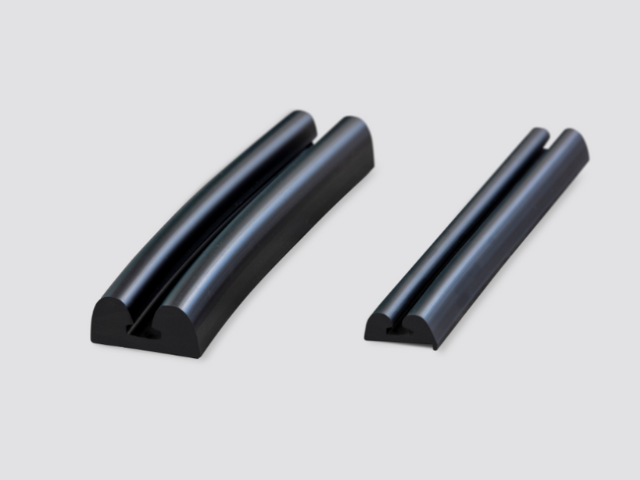

HANDRAILS

Wilks handrails are designed to clip over bars and surfaces. This is to allow for increased protection of the highly used areas they are applied to. Specifically, profiles are available to fit a 50mm x 9mm bar and a 40mm x 8mm bar. Both are available in black, with the smaller size also available in a traditional finish.

CORNER GUARD

Wilks corner guard fendering is able to be applied to edges that can run either horizontally or vertically. These guards offer increased protection to potentially vulnerable areas. The corner guard is designed to fit an aluminium retainer profile.

ANCHOR RECEIVER

What fendering Profiles are right for me?

Still not sure which Wilks fendering is for you, simply answer the following questions for further guidance.

What is the boat’s purpose?

To determine the most suitable profile for your boat, consider its intended purpose. For instance, a heavy-duty D profile might be ideal for a working boat, while a sleek and lightweight option like aluminium or rigid PVC could better suit a day cruiser.

What is the intended fendering location and size?

Identifying the desired location for the fendering also aids in narrowing down the selection process. As it provides crucial details regarding the required size of profile. The size correlates with the space it needs to fill. Profiles within the same range or category may share similar designs but can differ in size. If one profile doesn’t adequately fit the allocated space, there might be another available with the same profile design.

For instance, the Click range offers four sizes, spanning from 38mm to 150mm in width. D fendering comes in various sizes, ranging from 22mm to 100mm in width, offering different heights and wall thicknesses. U profiles represent the largest category, with 29 profiles available, ranging in width from 8mm to 45mm.

Is the surface to be protected – flat or flanged?

On your boat, it is important to identify the correct area for the fendering to be placed. Specifically, is it a smooth, flat surface or does it have a protruding flange?

On A Smooth/Flat Surface

For a smooth/flat surface, selecting a profile that accommodates either a flat side or a stepped join is crucial, depending on your boat’s design. If the hull of your boat is vertically straight where the fendering is to be placed, opt for a profile with a flat side, such as D profiles and Bump!, which are popular choices. However, if your boat has a curved or angled hull, a stepped join profile is more appropriate. These profiles feature a ‘leg’ to adapt to the hull’s shape changes, ensuring the fendering is optimally positioned.

On A Flange

When dealing with an outward hull flange, opt for a U profile. A flat flange requires a smooth internal channel on the U profile, such as PVC 2010. In cases where there are rivets and bolts on the flange, it would require a profile capable of handling such features, like PVC 4/2. Wilks’ U fendering range offers both flat and riveted flange solutions, ensuring you find the perfect fit for your boat.

What Accessories do I need?

Wilks fendering profiles also have a range of accessories that are sold individually. Depending on the profile you are considering, some of the following accessories may be required. These can include fixing strips, plugging, end caps or inserts.

End Caps: End Caps are a finishing accessory, providing a sleek stainless-steel or PVC conclusion to the length of fendering, usually used at the transom.

Inserts: Inserts are available in PVC or stainless steel and are fitted with the corresponding ‘Body’.

Fixing Strips: These tend to be used for B and D profiles. When fitting the profiles, the rigid strips act as a strengthening bar and help prevent the screw heads pulling through the fendering.

Plugging: This is used for D profiles, after installation it can be used to fill any holes made from screws to ensure a professional finish.

What material is Wilks Fendering Available in?

Since boats vary significantly, Wilks fendering range is available in various materials to suit different needs.

- PVC: Polyvinyl Chloride (PVC) represents the main material that Wilks fendering profiles are manufactured from. The profiles are extruded from a UV-Stabilised and Phthalate-free compound ensuring durability and resistance to weathering. Additionally, it is non-marking, so is an ideal material for marine applications.

- MDPE: Medium-Density Polyethylene (MDPE) is known for its excellent strength-to-density ratio. With flexibility, toughness, and low-friction status, these profiles are well suited to a wide range of applications including in the marine environment. It is capable of withstanding both high and low temperatures, making it suitable for a wide range of climates.

- Stainless Steel: A selection of Wilks fendering accessories are made from stainless steel, including inserts and also End Caps. These products have exceptional corrosion resistance and strength supporting good looks and long life of the products.

- Aluminium: The ‘ALI’ fendering range is made from aluminium. It is known for its strength, lightweight and aesthetic appeal. The ‘ALI’ range is supplied with an anodised or anodised and polished finish. The anodising process boosts the profiles durability and corrosion resistance whilst the polishing enables a smoother, shinier finish.

A frequently asked question regards the differences between the Rigid PVC fendering range and the aluminium range as they are similar profiles? The answer tends to be based on personal preference. Although, for downward curves, such as where the gunwale bends into a bathing platform, rigid PVC may be more suitable. As heat can be applied whilst fitting the profile, so that it can conform to the angles easier.

Still not sure which fendering profile you need, we are here to help. Send us a clear image or small sample of your existing fendering, and we can try to match it for you.

What Colours are the profiles available in?

Most of the Wilks fendering profiles are provided in black or white as standard. We also offer our ‘Traditional’ range, which mimics the appearance of real wood. If you are looking for something truly unique, some profiles and inserts are available in bright blue or red.

Can’t find the colour you like? We are able to produce custom colours, just contact our Wilks / Flexiteek sales team to discuss the possibilities.

What Lengths are the profiles available in?

Wilks fendering range is usually stocked in convenient ‘boat lengths’ i.e. 10m, 15m, 20m or 30m coils. Some of our heavy-duty profiles are supplied in shorter lengths, to make the profile more manageable and safer to handle when fitting. Although it may mean the profiles are needed to be butt joined in places.

How much fendering do you need?

Once you have identified the correct profile for you, the next step is to work out how much fendering you require. Two measurements are required for this calculation – Boat length and the beam (width). Double the boat’s length, add the boat’s beam (width) and then add a further 1m-2m in order to allow for the hull’s radius.

If you want to confirm the profile but don’t want to commit to buying the full coil just yet, ordering a sample of your fendering can be beneficial. Due to reduced shipping costs and effort in terms of returns. To request a sample of any stock items, you can do so either via the particular product page or by contacting us directly.